I might have been a liiiiittle fast out of the gates, proclaiming the new Non-Inventory items to be the next cure for AIDS.

Ralf Daugbjerg from Elbek & Vejrup tested the solution a little further than I did, and it seems that Microsoft haven’t thought this functionality through all the way.

Value Entries with a value in the “Cost-Amount (Non-Invtbl.)” field are costs, that do not create any G/L accounts according to Olof Simren’s blog post: https://www.olofsimren.com/things-to-know-about-item-charges/, they only serve to increase the cost.

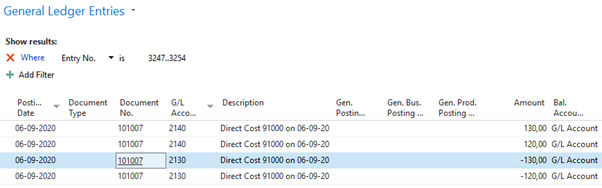

This means that they will add a cost to e.g. a sales order without interfering with the inventory. In this case, the added cost is not added to the WIP G/L account, but it is added to the calculated WIP value of the production order. Which again means that, when the WIP account is emptied after changing the production order status to Finished, the added cost stays at the WIP account as a negative value.

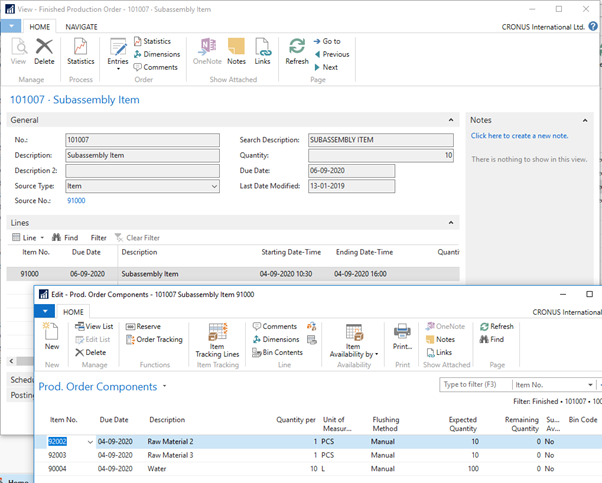

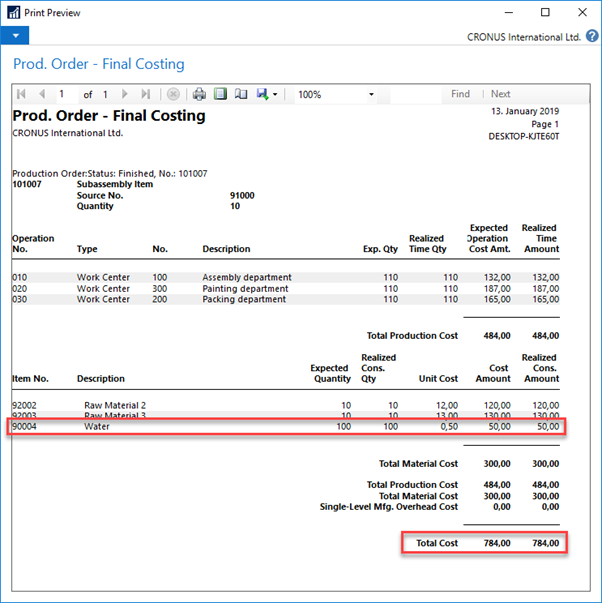

Let us test it. This was the production order from previous:

Posting the component consumption looked like this:

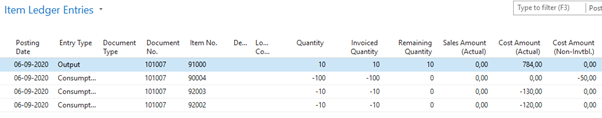

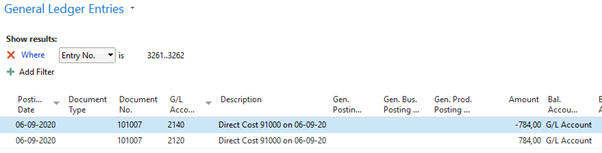

But the Inventory Batch only did this:

Which is, the physical items is taken out of Inventory (2130) and moved to WIP (2140).

The problem is that when the status of the production order is changed to finalized, the full amount is then moved from WIP back to the inventory.

In this case the full cost of 784,00.

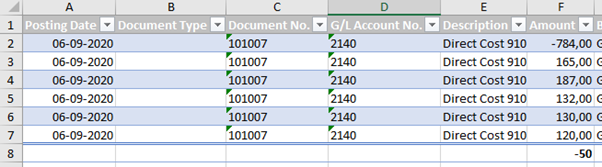

So, looking at the total amount of transactions on the WIP, it looks like this:

I knew it was too good to be true

Come to think of it, it is not surprising, because where should the cost for the water be balanced.

We do not have a G/L account for the “Cost-Amount (Non-Invtbl.)” amounts.

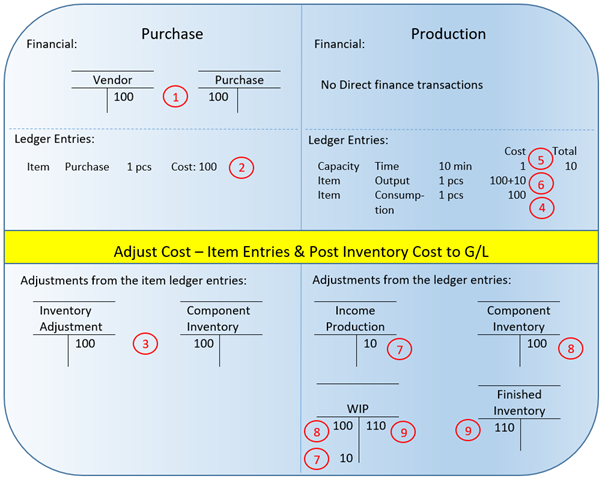

The normal costing for a production order looks like this:

Starting In the upper left corner:

- Item is purchased and the cost end up in the purchase account

- The Value Entry is created with the purchase

- The Inventory Batch runs and move the cost via the Inventory Adjustment account to the Component Inventory account using the Value Entry as basis.

- The components are consumed and therefore moved to WIP.

- Operators add capacity costs to WIP.

-

Finished Goods are produced ending up in the Finished goods Inventory

Then the Inventory Batch is run:

- The added value in form of hours rates or costs per produced item is added to the WIP and the balance account will be the “Salaries transferred to production” account.

-

The consumed Item is moved from the Component Inventory account to the WIP account.

After The production order status has been changed to Finished:

- The Finished Item is moved to the Finished Inventory Account

The capacities that are posted “Salaries transferred to production” account find their account from the Gen. Prod. Posting Group on the capacity.

But we do not have an equivalent account for “Cost-Amount (Non-Invtbl.)” amounts.

So that was not a good idea, and it should not be possible to add the Non-Inventory items to the Bill-of-Materials just like the service items.

As a work-around it is possible to create a report specifying the total amount of Water transactions and the manually post them out of the WIP account and into the expense account for water.

The other alternative is to keep the previous procedure using an Inventory item and just add a whole bunch of water items to the inventory and keep the Inventory value Zero.