In just about every Manufacturing course that I have conducted, I get the same question: “What does the Update Unit Cost do when Changing the Production Order Status?”.

If we look at the latest course materials from NAV 2009, the explanation is:

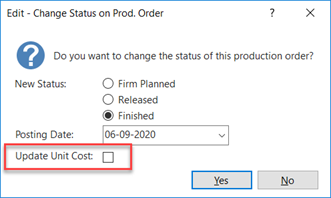

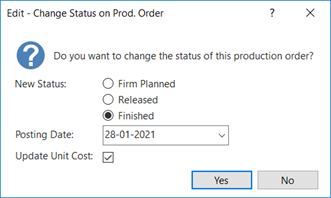

The window, shown in the figure, allows the user to select the desired status for this production order. Enter the appropriate Posting Date and select whether the unit costs of this production order are updated by placing a check mark in the Update Unit Cost field.

This is a quite ambiguous phrasing and it could mean everything.

Regarding my own book, I hate to admit that I have been equally wage in my phrasing of the topic.

Therefore, to set this straight I have once again resorted to the code to figure out, what the field actually does.

First of all, it is clear that the field only affects Items with these costing methods:

- FIFO

- LIFO

- Specific

- Average

So, it has no effect on items with the standard costing method.

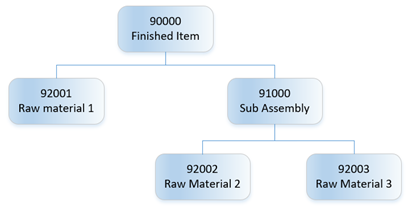

But let us test what it is all about. Firstly, I will create items in a multi-level BOM structure:

All Items are using the FIFO costing method and all produced items has a lot size of 10.

I have disabled the automatic Inventory Batch (Adjust Cost and Post Inventory to G/L) to make it clear which function is doing what.

I have purchased raw-materials:

1000 pcs Item 92001 at 10

1000 pcs Item 92002 at 11

1000 pcs Item 92003 at 12

1000 pcs Item 92004 at 24

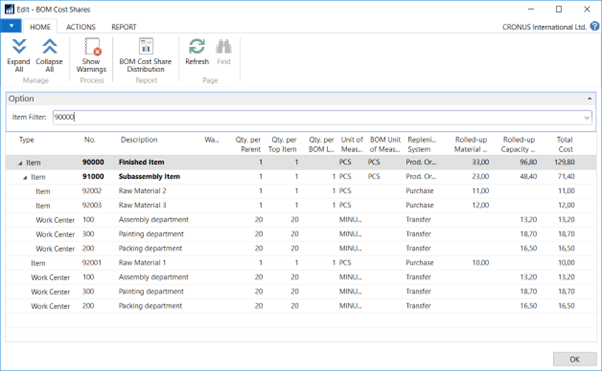

I have calculated the prices using the Cost Shares function:

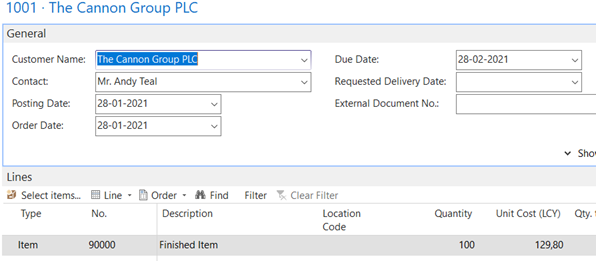

I create a Sales Order with 100 pcs of Item 90000 and create a firm planned production order from the sales order. Already now, the price should differ because of the change in the lot size.

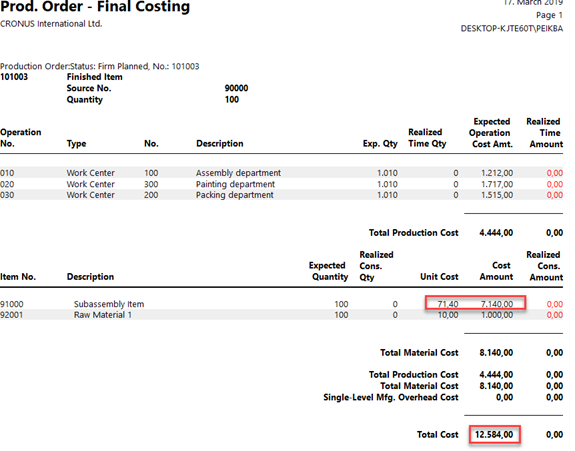

Checking my own Final Costing report from my previous blog post, I see the new calculation:

And already here, I can see that the prices are off. The Unit Cost from the Sub-assembly is the same as previous It should be 67,44 given the new production size and the finished item should be 121,88.

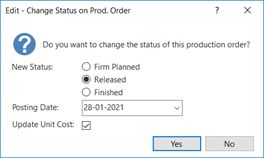

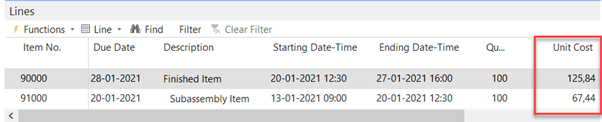

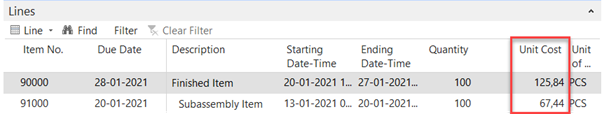

Changing the status to Released on the production and setting the Update Unit Code field will give this result on the production order:

Not quite what I expected, but it’s getting closer.

On the sales order the Unit Cost has changed into this:

Not all the way, but we are getting there.

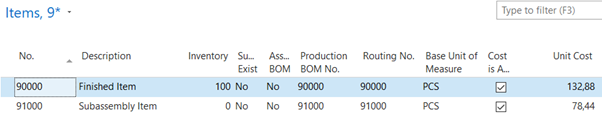

Now I am going to produce the subassembly and add one more raw material at the price of 11 changing the cost to 78,44. Then I produce the Finished item with the estimated consumption and the finished item to 132,88 including the new cost for the sub assembly.

Lastly finalizing the production order

And then I run the Inventory Batch.

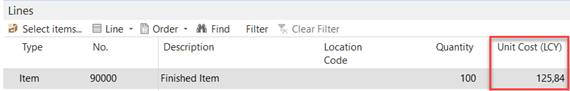

The Finished Production Order still holds the same unit costs as before:

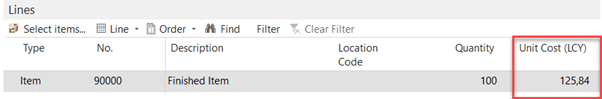

And the Sales Order has not been changed either:

But of course, the Unit Cost on the Item are updated correctly:

Conclusion

Changing status from Planned to Firm-Planned or from Firm-Planned to Released, the unit cost is updated BOTH on the Prod. Order lines and on the Sales Order where the demand originated from. However, changing from Released to Finished, the unit costs are not changed at all.

Also, on multi-level production orders the unit cost from the item is being used calculating the unit cost for the top-level, making this functionality sketchy.

So, does it work?

Not in my book. In order to work properly, the rolled-up unit cost should be updated, on the production order as well as on the sales order line regardless of the status it ends up in.