A production order can be created in four different statuses. In three of them, it is not a problem if a production order was created by mistake. The “Simulated”, “Planned” and “Firm Planned” production orders can be edited or deleted endlessly. However, the “Released” production orders can be edited and deleted freely until the first posting has been made. Then it is no longer possible to delete.

This is a problem if the components of the production order or the capacity of the routing of the production order has been set up with forward flushing. This will post the components or the time consumption when the production order is released or a released production order is refreshed. This also means that a production order that is accidentally released cannot be returned back to the previous status, and certainly not deleted.

Why?

Because entries exist on the production order. This means that one of the following tasks have been performed:

- Consumption has been transferred from inventory to Work in Progress (WIP). The consumption will create an item ledger entry and a value entry.

- Consumed time has been registered to the production order. This will create a capacity ledger entry and a value entry.

- Output has been registered to the production order. The output will create an item ledger entry and a value entry.

So in order to delete the production order, it is necessary to:

- Reverse all consumption transactions. (Watch out for the cost price of the returned item)

- Reverse all capacity ledger entries with the time consumptions

- Reverse all output transactions

- Change the quantity of the finished item to 1 and post the output

- Reverse the output.

This can be done in the production journal.

An example:

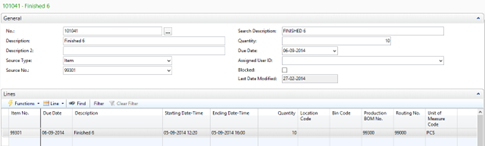

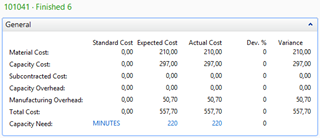

Production order 101041 has been created, and postings have been made by mistake.

There are all types of entries posted to the production order:

Item ledger entries, both consumption and output:

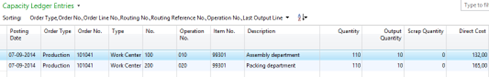

Capacity ledger entries:

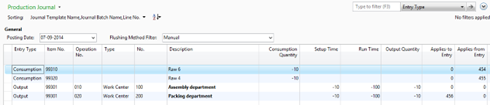

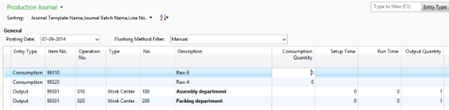

So all transactions are reversed:

A special thing to remember is that the output of the last operation must be applied to the original output item ledger entry to ensure correct reversal. The consumption can be applied from the correct item ledger entry for the same reason.

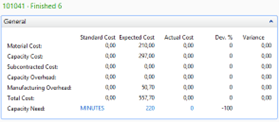

This will reverse all costs on the production order:

Now all that is left is to change the quantity to 1 and post the output.

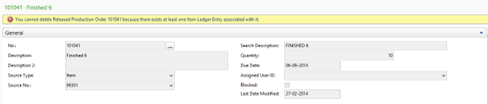

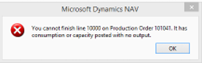

Is this really necessary? Yes, otherwise the Change Status on the production order will fail with this error:

So there is no way around.

Now the output has been posted with a value of zero:

This posting must be reversed in the item journal. Remember to apply to the output entry.

Now the production order can be changed to “Finished”.

Should this be an automated function? Possibly – if the components have been set up with forward flushing, then it could be an idea. Otherwise, it is okay that the reversal is a little bit difficult, just to encourage users to get it right the first time.